An in-house analysis laboratory: a great step forward in quality

The design of a liquid, its verification in real time without the need to use third parties, allow us to offer products with certainty as to the composition of all the components present and, in particular, those that are now under quality monitoring by the bodies that have defined the compliance protocols for electronic cigarette liquids.

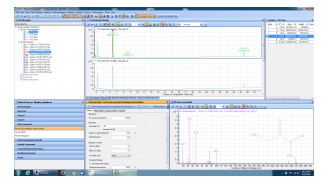

Since the beginning of August, a gas chromatography (GC-MS) system has been in operation in our laboratory, a state-of-the-art piece of equipment that allows us to significantly raise the general quality level of our Company. The choice made is in line with a company policy that aims to raise the quality level more and more, both in absolute terms and with reference to the regulatory system referring to the European Directive on Tobacco Products as implemented in Italy by Legislative Decree 6/2016.

The design of a liquid, its verification in real time without the need to use third parties, allow us to offer products with certainty as to the composition of all the components present and, in particular, those that are now under quality monitoring by the bodies that have defined the compliance protocols for electronic cigarette liquids.

Once the design phase has been completed, the liquid is analysed in its final formulation to validate its compositional aspects also in the vapour phase.

Our in-house laboratory also allows us to verify the conformity of incoming raw materials, checking the basic quality of any product used for a greater guarantee of the overall quality of each blend.

We can claim to be one of the few companies in the world, whose core business is the exclusive production of electronic cigarette liquids, to have installed such sophisticated equipment. Equipment that can be found in food industries or control bodies such as the NAS, ARPA and ASL or health facilities.

The laboratory, moreover, is connected with other scientific realities, expanding the possibilities and potential for verification and control. Thanks to these synergetic relationships, we have also developed a system for verifying the vapour, not just the liquid, making use of highly refined technologies that allow the analyses to be carried out without using 'headspace' adsorption and de-absorption systems, the so-called SPMEs, but using electrospray technology, i.e. an ionisation source connected directly to the gas mass. The comparison between the liquid and vapour phase allows us to really understand what is happening in the liquid/vapour transition and assess with absolute precision what is being inhaled by the vaper.

We are then able, in essence, to re-proportion the formulation on the basis of actual emissions and not just on the liquid mixture. We are no longer talking about a banal smoke-machine but something enormously more advanced and sophisticated.

The technology is now also available to other companies that are making use of this know-how and that, thanks to the investments made in the plants, can have this technology available at very competitive costs.

We are convinced that quality control is a due act towards consumers and that the checks and controls that predefine the quality of the final product are also important to make the outside world understand that vaping has become an important phenomenon that has made rapid and exciting progress in recent years.

Comments

No comment at this time!

Leave your comment